Mmi

10 Rue Edouard Denis Baldus

71100 Chalon

Phone : +33 (0)3 85 97 13 43

Email : mmi@groupe-empreinte.fr

AMBIGRAM & MY COMPUTING (Flexite)

66 RUE MARCEAU

71200 - THE CREUSOT

Siret : 790 161 061 00011

Phone : 03 73 27 06 90

Email : contact@flexite.fr

The user is informed that, in accordance with the article 27 computer law, files and freedoms 6 January 1978, les informations communiquées par l’utilisateur du fait des formulaires présents sur le site sont nécessaires pour répondre à sa demande et est exclusivement destiné à MMI. L’utilisateur est informé qu’il dispose d’un droit d’accès et de rectification portant sur les données le concernant en écrivant à l’adresse suivante : mmi@groupe-empreinte.fr. Website users http://www.moules-modeles-industriels.fr are required to comply with the provisions of the Computer Science Act, files and freedoms, whose violation is punishable by criminal sanctions. In particular, they must abstain, s’agissant des informations nominatives auxquelles ils accèdent, of any collection, of any misuse, generally speaking, any act likely to harm MMI, privacy or the reputation of individuals. The general structure, as well as the texts, animated images or not, savoir-faire et tous les autres éléments composant le site sont la propriété exclusive de MMI. Any full or partial representation of this site by any company, sans l’autorisation expresse du Cabinet du responsable de la publication est interdite et constituerait une contrefaçon sanctionnée par les articles L.335-2 et suivants du Code de la propriété intellectuelle. Any full or partial reproduction of trademarks or logos, based on the elements of the site without the express permission of the rights holder or rights holders relating to it is therefore prohibited, Section L.713-2 of the Intellectual Property Code. Les liens hypertextes mis en place sur le site peuvent conduire l’utilisateur sur divers sites. It is specified that MMI has not verified all sites possibly related to its, their content and the information it contains, and invite the user, under his responsibility, to validate compliance, accuracy, completeness and/or legality of the information and/or content they have access to on these sites. MMI décline par conséquent toute responsabilité sur les contenus et services offerts sur les sites auxquels le visiteur a accès à partir d’hyperliens de son site http://www.moules-modeles-industriels.fr and user use. Le recours à ces sites par l’utilisateur relève de sa seule responsabilité. Les utilisateurs et visiteurs du site Web ne peuvent mettre en place un hyperlien en direction de ce site sans l’autorisation expresse et préalable du responsable de la publication. MMI met tout en œuvre pour offrir aux utilisateurs des informations et/ou outils disponibles et vérifiés, but cannot be held responsible for any of the errors, lack of availability of information and/or the presence of viruses on its website.

MMi is your partner for your plastic transformation processes by thermoforming in any sector of activity

Can be used for all market sectors, Thermoforming is an economical and fast solution. To support the development of your projects, on which MMi will be delighted to be your partner.

60 years of experience

We have been able to draw from our 60 years of experience, advanced human and technical skills to control the deformation of plastic plates in the technique of thickness thermoforming.

From food to packaging

We partner with each player in this technology for the best realization, Improvement of your manufacturing tools by fine thickness thermoforming in coils.

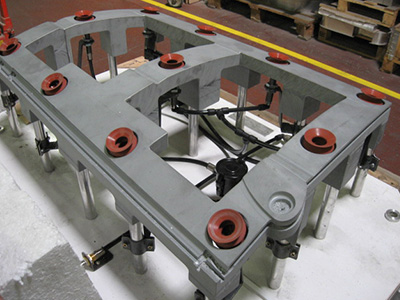

MMi complements its tooling production with skills in the manufacture of medium or resin clipping jigs, Suitable for your cutting machine. MMi is also able to study and deploy, Systems that optimize your industrialization and internal processes. All these capital goods are the result of a joint reflection and adapted to your environment

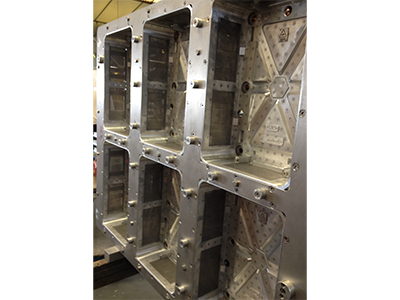

We design and build tools for the processing of expanded materials such as PES/EPS, EPP/EPP, Epe, AIRPOP.

Our know-how allows us to adapt to your request in order to meet your expectations on different types of tools. :

Tools with light CDC to limit the budget for casting small series

Tools with CDC optimized to guarantee several hundred thousand cycles (we have to date several tools that have exceeded one million cycle without action/maintenance on our part)

Tools with CDC establishes specifically for molding parts with mechanisms, metal/plastic insert, surface treatment (chemical or laser graining), porous bronze and other specificities

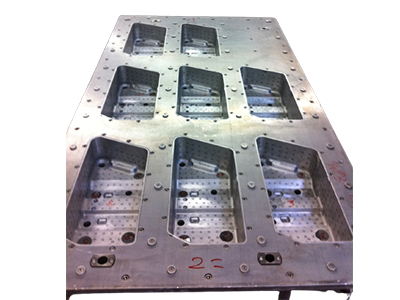

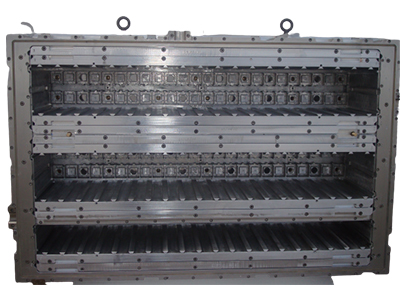

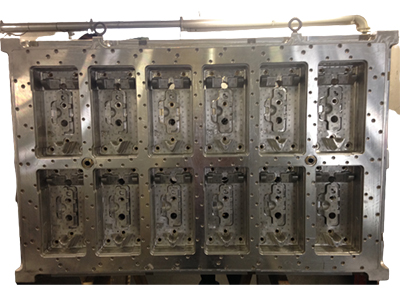

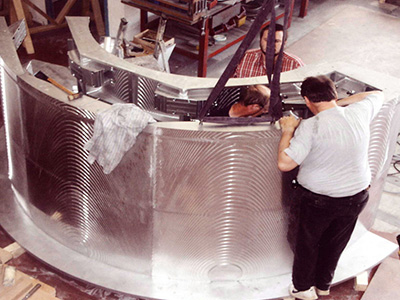

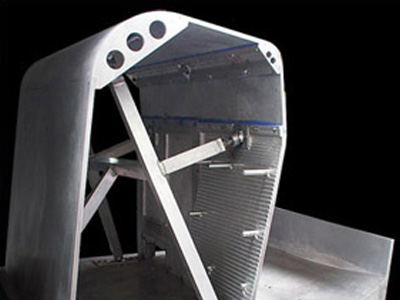

Below are various illustrations of tools made in our workshops

Material increasingly used in many sectors, The composite can be declined under different manufacturing processes.

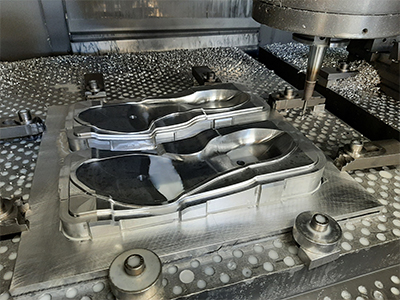

MMi has listened to the market and done R&D by working with bio-sourced composite materials for aeronautics, Automotive and aerospace. MMi carries out high quality work for the realization of molds and tools and in the transformation of composites (silicone vacuum tarpaulin, soluble cores for hollow parts). MMi is able to machine masters for the realization of your small series.

Made by Stand 21 with a mold made in our workshops